Welcome to the official website of Guangxi Ardon Machinery Co., Ltd.!

Types and daily maintenance methods of LiuGong original factory tires

Release time:

2025-04-24

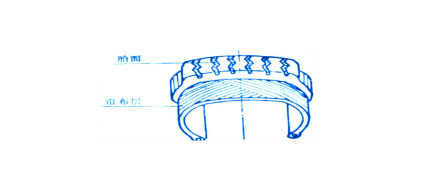

Bias tires (with adjacent layers of fabric in the carcass and buffer layers crossing each other), including solid tires and semi-solid tires. Most of the tires currently sold by LiuGong are bias tires.

I: Types of Liugong Loader Tires

• Bias Tires (The plies and buffer layers have adjacent plies crossing each other), including solid tires and semi-solid tires. Most of the tires currently sold by Liugong are bias tires.

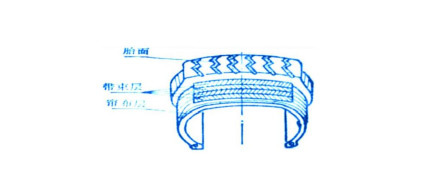

• Radial Tires (Steel-belted radial tires): The plies are arranged at a 90° angle to the center line of the tread, and the tire body is tightened with a belt layer. Steel-belted radial tires are a new generation of bias tires, they are more durable, and the driving experience is also better, but the price is much more expensive than bias tires. Steel-belted radial tires are mainly used in trucks, buses, and bridges. Engineering machinery currently uses steel-belted radial tires less, mainly for large-tonnage equipment. Liugong loaders of various tonnages are equipped with steel-belted radial tires.

Remarks:

|

Steel-belted radial tires Steel-belted radial tires, also known as radial tires, are upgraded products of bias tires. They have greater advantages in terms of materials, structure, and performance. Compared with bias tires, the service life and load-bearing pressure can be doubled. |

|

Solid tires Solid tires are mainly used in high-temperature and explosion-prone working conditions, such as steel plants and boiler plants. |

II: Tire Selection Guide

|

|

||

| Applicable Working Conditions |

Level |

Remarks |

| Suitable for most ordinary working conditions, such as coal yards and sand yards |

16 Ply |

5 Standard configuration for tonnage loaders. Selecting this level offers the highest cost-effectiveness according to the specified load. |

| 20 Ply |

For working environments with frequent overloading, choose high-ply tires. The higher the ply rating, the higher the load. |

|

| 24 Ply |

||

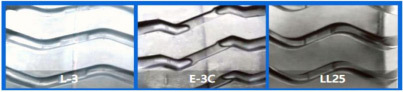

2. L-5 Deep Tread Pattern

|

Remarks L-5 deep tread pattern tires, also known as semi-solid tires in the market. This tire has a relatively deep tread pattern and is mainly used in working conditions where the inner tube is easily punctured, such as glass factories, aluminum factories, iron mines, crushed stone, and pebbles. |

III: Tire Maintenance and Care

• When parking, choose a shady place and avoid parking on slopes or roads with large, sharp stones.

• When parking on the side of the road, be as careful as possible to avoid rubbing or colliding with the roadside, preventing sidewall damage and potential hazards. Remove any small stones, nails, or sharp debris from the tire tread in time to prevent them from embedding in the tire and causing leaks.

• Remove any debris between dual tires promptly, otherwise it will also damage the tires.

• If there are small holes on the tire surface, repair them promptly to prevent mud and sand from entering the plies and causing delamination.

• Paying attention to the maintenance of engineering tires can effectively prevent early tire damage, ensure construction safety, and improve work efficiency.

keyword: contact, seal ring, locknut, bolt, nut, pipe, lock, latch, door hinge, fan

More News